Industrialized Housing Delivery in the U.S.: Recommendations for State and Local Governments

AUTHORS: Ivan Rupnik, Ph.D., Ryan E. Smith, Ph.D., Tyler Schmetterer, Benjamin Preis, Ph.D., and Lauren E. Leonard

Key Points

- Industrialized Housing Delivery means integrating design and planning, offsite manufacturing, and onsite assembly into a coordinated set of value-added activities for housing construction.

- Achieving industrialized housing delivery at a large scale means combining building code updates with the demand for housing.

- Nations such as Sweden and Japan lead the way on industrialized housing delivery and provide lessons for both of these steps.

In the U.S. today, almost all housing — single-family homes, townhouses, small apartment buildings, and large apartment complexes — are built through traditional, onsite construction, where workers assemble the materials and construct a building on the ground on which it will be occupied. Offsite construction, where a portion of the material assembly is done offsite in a factory before being transported to its destination for final assembly, can accelerate home development and increase housing supply at scale. The most advanced form of offsite construction, “industrialized housing delivery,” utilizes practices and methods associated with other fields of manufacturing to engage all parties from project inception and maintain this collaboration throughout delivery to increase efficiency and improve outcomes. However, the varied and layered building and land use requirements of states and local governments currently favor conventional design-bid-build site-built construction, limiting adoption of offsite construction methods in the U.S. even as other developed countries continue to lead in using these approaches. State and local governments can implement targeted reforms and actions to modernize and harmonize building codes to propel the offsite construction industry forward and effectively address the housing affordability crisis.

International examples like Japan, Sweden, and parts of the UK and the European Union demonstrate that governments leading through regulatory reform and demand aggregation actions can successfully accelerate and scale offsite construction. Regulatory reform includes aligning building codes across jurisdictions to eliminate arbitrary differences and streamline the process of permitting buildings for construction, which would decrease cost and increase efficiency for all types of housing, including offsite. In the U.S., regulatory reform would be achieved by migrating from the current “prescriptive” building code framework — which dictates the types of building materials and techniques given the size and use of a building — to performance-based building codes that focus on how building materials and construction techniques should perform. Demand aggregation is also often seen in successful modular construction efforts, as it creates the consistent project pipeline that offsite construction entities need to justify upfront factory investments and align with local, state, and federal governments on incentives and award criteria.

States and localities can accelerate the adoption of industrialized housing delivery by changing regulations and incentives, and procuring housing in ways that encourage greater speed, reliability, and consistency — areas where offsite construction excels. This includes different forms of demand aggregation, such as changing award criteria from housing authorities, city housing departments, and housing finance agencies for private-sector developers to focus on the total project cost, project delivery timing, and product consistency — areas where industrialized housing delivery can excel. In Virginia and Minnesota, state and local leaders have been taking steps towards these changes, as highlighted by the case studies in this tool. Additionally, states and localities can pursue building code and land use reform, including the adoption of new standards from the International Code Council and Modular Building Institute, toward a long-term shift focused on performance-based building codes, as has been done in Utah, Montana, and Virginia. In partnership with MOD X — a research-based advisory group focused on advancing the industrialization of construction to achieve broader societal goals— HUD and the National Institute for Building Sciences (NIBS) are also developing educational programming, strategic action plans, and implementation roadmaps to support state and local adoption of these regulatory solutions, and accelerate industrialized housing delivery.

The Challenge This Tool Solves

Construction costs have doubled over the last decade across the housing type spectrum, including for-sale, for-rent, market-rate, and affordable housing, driven largely by a national construction workforce labor shortage, increased material costs, and regulatory requirements that result in more time-consuming and expensive housing developments. Offsite construction can reduce costs by implementing manufacturing principles thereby optimizing labor, leveraging economies of scale, and improving material efficiency. Fostering a high-technology housing sector can address the current crisis and serve as a framework for the future of housing production across the U.S.

Types of Communities That Could Use This Tool

This tool may be used by states and localities that oversee building codes and directly or indirectly procure housing through the disbursement of grants, loans, and awards. Partners in advancing knowledge and research may include code councils, institutional housing, economic development think tanks, labs, and related nonprofits. Adopters may consist of state and city governments, metropolitan planning councils, public housing authorities, community and neighborhood housing organizations and consortia, offsite and industrialized housing companies, and developers.

Expected Impacts of This Tool

Our current regulatory framework, contracts, financing, insurance, and modes of project delivery are currently oriented around onsite construction. This tool aims to amend that framework placing conventional construction and innovative modes like offsite construction on a more level playing field to better utilize both delivery methods to achieve societal goals. By creating a framework more supportive of onsite and offsite industrialization and innovation can we properly address the nation’s increasing housing affordability and supply crisis. Implementing these institutional reforms at the state and local level provides the long-awaited possibility of accelerating innovative forms of construction that will in turn help increase housing supply, affordability, quality, durability, and performance. While tools like these have been proposed in the U.S. for more than half a century, they have never been fully applied and realized, but have proved demonstrably successful in other countries that share economic and political similarities.

Offsite construction is categorized by the scale of the key structural elements transported from factories to construction sites for assembly. These include so-called “one-dimensional” structural elements (usually referred to as a “kit of parts”), two-dimensional elements (often referred to as “panelized”), and three-dimensional volumetric (usually referred to as modular) elements. Offsite construction is further distinguished based on the degree of enhancement of an element in a factory setting, from purely open structural components to enclosed elements that may include utilities, insulation, and interior/exterior finishes. While three-dimensional modular housing is often the focus in policymaking circles, it is but one form of offsite construction techniques.

Industrialized housing delivery (IHD) goes beyond offsite construction — integrating design and planning, offsite manufacturing, and onsite assembly into a coordinated set of value-added activities. Unlike the fragmented design-bid-build approach dominating U.S. construction, IHD engages all parties from project inception and maintains this collaboration throughout delivery to increase efficiency and improve outcomes. Achieving maximum impact requires long-term planning and investment. The IHD approach balances standardization and customization, resulting in a turnkey housing product developed by a vertically integrated company that can achieve efficiencies in scale and continuous learning. Teams consisting of design and engineering professionals, offsite manufacturers, and onsite builders from unique companies can practice IHD through early coordination on a per-project basis and preferably extending relationships over multiple projects. An IHD team requires a third-party system integrator, a lead stakeholder in project delivery, who can manage and monitor the entire process — this level of integration is necessary to achieve the cost savings and construction time efficiencies available through this method.

Current regulations, contracts, financing, insurance, and training infrastructures are geared toward piecemeal site-built construction rather than a manufacturing-oriented production innovation system, creating challenges for IHD despite its potential. This tool seeks to eliminate these barriers to the application of IHD.

Accelerate IHD to Increase U.S. Housing Supply

With support from the U.S. Department of Housing and Urban Development (HUD), the National Institute of Building Sciences (NIBS), and others, MOD X has developed a model for effectively accelerating IHD for housing at any scale based on lessons from internationally evolved offsite construction contexts. The model can serve as a tool for increasing housing supply and making a positive contribution to the U.S. housing crisis with two primary actions: (1) regulatory reform, and (2) demand aggregation. Combining regulatory reform with demand aggregation has proven effective at accelerating IHD in more evolved industries abroad including Japan, Sweden, and the UK. Harmonizing regulations across as large a market area as possible and shifting away from prescriptive codes towards performance-based specifications has proven to be an impactful strategy.

Over the past 50 years, Japan and Sweden have employed both regulatory reform and demand aggregation to accelerate and scale IHD. Over time, the growth of this sector has encouraged increasing technological capacity, allowing the sector to expand and contract its supply of new housing in-line with demand. This sort of flexibility is already common in mature automotive, aerospace, IT, and food production sectors, but need to be further adapted and adopted by the housing sector in the U.S. to truly treat housing as an industry.

Regulatory reform without demand aggregation has eliminated many of the barriers to the acceleration and scaling of IHD. However, increased supply often materializes slowly to address a housing crisis. Demand aggregation without regulatory reform can provide an immediate increase in housing supply but can also create an IHD industry sensitive to fluctuations in demand and highly dependent on government programs and subsidies. Demand aggregation without regulatory reform can also lead to a lower-quality product to meet a short-term goal from the public sector, leading to long-term market stigmatization of offsite construction. As such, regulatory reform and demand aggregation go hand-in-hand.

Regulatory Reform Action

The frameworks regulating housing development and construction in the U.S. evolved over more than a century and will likely take many decades to further evolve with strong state and local action. These historical frameworks unintentionally prescribe the conventions of onsite construction, inform other institutional frameworks regarding labor, contracts, financing, and insurance, and, in turn, require offsite construction to conform with practices and standards developed for a different kind of construction method. Like conventional construction, these regulatory frameworks are highly localized and varied, presenting barriers to IHD. Without institutional and structural transformation, offsite construction and IHD will continue to be regulated by logics based on onsite construction methods and will continue to struggle to outperform conventional construction.

In contexts where IHD has successfully accelerated and scaled, direct government action has been essential for implementing and refining effective long-term policy reforms. Sweden and Japan have completed this process with a regulatory framework placing offsite and onsite construction on equal footing. In the UK, Australia, New Zealand, the European Union (EU), and several other countries, this regulatory transition is underway. In the U.S., various regulatory reforms, directly initiated by HUD or other governmental and non-governmental entities, have significantly improved the situation. One of the first successful attempts to reform the U.S. regulatory environment was the introduction of state industrialized building programs, starting with California in 1968. These programs ensure that a regulatory framework appropriate for offsite construction exists in more than 30 states. The most impactful national-scale regulatory reform was HUD’s revision of mobile home industry standards into a federal standard that supported the creation of the higher-quality but equally affordable manufactured housing sector in 1976. The shift in the regulatory framework from a multiple regional model code to two in 2000, managed by the International Code Council, also had a harmonizing impact on all construction. Most recently, following recommendations made by MOD X to the Modular Building Institute (MBI), MBI teamed up with the ICC to develop procedural standards for the inspection and permitting of volumetric modular construction. However, additional reforms are required to continue moving the industry forward and addressing the current housing crisis.

Based on international precedents from forthcoming MOD X research, effective regulatory reform occurs via three, often related policy initiatives:

Harmonization of Building Code and Land Use Regulations Over a Substantial Market Area: Current U.S. land use codes are fragmented across thousands of local governments, and often restrict housing size, shape, and density such that standardized IHD products are unsuitable. Additionally, prescriptive-based building codes are often implemented differently across jurisdictions, which may have their own amendments to national model codes. Locallybased inspection and building permit processes require developers to navigate complex regulatory environments. Harmonization of building codes and land use regulations over a large market area eliminates arbitrary differences in specifications and can improve the efficacy of both conventional and offsite/IHD construction methods. Harmonization can occur through the preemption of a national regulation over local regulations (e.g., Japan in 1950, Sweden in 1960, and the US in 1976 via the HUD Code) or through the introduction of model regulation incentivized for adoption by local governments (e.g., Eurocode in the European Union since 2010, International Residential Code (IRC) and International Building Code (IBC) developed by the International Code Council since 2000). In Sweden and Japan, comparable harmonization of land use codes nationally during the early postwar period positively impacted offsite construction housing quality and housing supply more broadly. At the state level, the Commonwealth of Virginia has attained a high regulatory harmonization level by essentially requiring all authorities having jurisdiction to adopt the state versions of model codes and industrialized buildings model code with no revisions.

Complete Transition From Prescriptive-Based to Performance-Based Specifications: In addition to the harmonization of regulations, shifting from a prescriptive- to performance-based building code specifications has proven highly effective in accelerating both IHD and improving onsite construction outcomes. Today, the U.S. largely uses a prescriptive building code framework — which dictates the types of building materials and techniques given the size and use of a building — rather than a performance-based building code that focus on how building materials and construction techniques should perform. However, the complete transition from prescriptive- to performance-based building codes takes time to achieve. The ICC is developing a major update to their current performance-based building code for the 2027 update.

Housing System Certification: An intermediate step towards performance-based specifications. The transition from a prescriptive to a performance-based code environment occurs over a period of time. For example, the 27-member state European Union is still in the process of fully transitioning to this regulatory framework, although some member states like Sweden have already fully transitioned. For this reason, several countries have implemented a housing system certification approach to create an alternate means of code compliance for innovative homebuilders. These companies are rewarded for requisite upfront investment in personnel, equipment, R&D, and resultant intellectual property through a fast-track code compliance process more attuned to a product than a project approach to delivery. HUD, working in close collaboration with the National Institute of Standards and Technology (NIST), pioneered system certification more than 50 years ago. Since that time, Japan has progressed furthest in scaling this approach with 1 in 3 homes moving through this streamlined path of code compliance. While Sweden and other European countries have not currently implemented full housing system certification processes, similar streamlined code compliance routes exist for new materials and prefabricated building components. In the U.S., ICC’s Evaluation Services (ICC-ES) could also serve in a similar capacity.

Demand Aggregation Action

Comparable to other capital-intensive manufacturing sectors, offsite construction and IHD require a steady pipeline to amortize requisite investments. Housing demand is highly varied in specifications and oscillates with macroeconomic variables. Demand aggregation in IHD acceleration can be defined as some form of government support including incentives, subsidies, and/or project contracts to create a more consolidated and stable production pipeline for the offsite manufacturing sector. Demand aggregation programs are particularly important in keeping factories in business during downturns. In Sweden, manufacturers often turn to public housing authorities (PHAs), which tend to build during economic downturns. In the U.S., Dynamic Homes, a Minnesota-based volumetric modular manufacturer, maintains a close relationship with various Native American tribes, who in turn benefit from specific subsidies.

Demand aggregation for IHD can be direct or indirect and typically occurs via three distinct forms:

- Direct demand created by the procurement of IHD for government-financed projects. Example: State Emergency Management Agencies (SEMAs) procurement of offsite manufactured housing to support emergency response efforts.

- Indirect demand created by the government-coordinated procurement of IHD by other entities. Example: Encouraging PHAs to prioritize innovative construction methods that include IHD approaches.

- Indirect demand created by coordinated award criteria for government-financed projects and subsidies. Example: Japan Housing Finance Agency (JHF) mortgage rate reduction program closely tied to the national housing system certification.

This sort of demand aggregation works best when the public sector procurement and coordinated award criteria focus on the areas where IHD can perform best: bringing down costs, decreasing time to completion, and increasing consistency across housing developments. To the extent that the public sector can create standard design criteria, this too brings down cost as the offsite manufacturers are able to streamline unit development and achieve economies of scale. Demand aggregation can further drive down costs when paired with pre-approvals and other expediting permitting.

Demand aggregation creates substantial impacts on IHD. First, it allows for the effective cost amortization to support capital-intensive innovation investments in R&D including technology, intellectual property, automation, etc., and critical labor resources. Second, it creates consistent and predictable product specifications, smoothing demand for new units over time and limiting customization at the unit level that typically exists in a highly fragmented housing market sensitive to long-term financial variables. Third, it signals to the private sector and to the general public that IHD is at least as high quality as conventional construction, if not more so, to consumers, end-users, financial and insurance sectors.

The conceptual model of regulatory reform and demand aggregation has been actively demonstrated through case studies in the U.S. Two case studies from Minnesota and Virginia illustrate these principles.

Case Study

Minnesota – Acceleration through Education and Standard Award Criteria

Industrialized Housing Delivery in the U.S.: Recommendations for State and Local Governments

As Commissioner of Minnesota Housing from 2011-2019, Mary Tingerthal realized the potential benefits of the greater adoption of industrialized construction techniques and identified the regulatory barriers impeding adoption.

Read More About Minnesota – Acceleration through Education and Standard Award Criteria

Case Study

Virginia – Acceleration Through Regulatory Harmonization

Industrialized Housing Delivery in the U.S.: Recommendations for State and Local Governments

The Commonwealth of Virginia is one of 35 states with an established industrialized building program responsible for administering and enforcing statewide standards for enclosed factorybased construction.

Read More About Virginia – Acceleration Through Regulatory HarmonizationIHD

Focusing on the goal of increasing housing supply, MOD X, NIBS, and HUD have partnered to accelerate the adoption of innovative and effective IHD practices and policies around the country. Working closely with several U.S. regions, the group is developing Regional Action Plans and Pilot Programs to:

- Identify regulatory and demand aggregation barriers to IHD in each region; and

- Develop strategic plans to support regional IHD growth.

The findings will inform the development of a HUD Breakthrough Pilot Handbook, a technical assistance resource to support states, regions, counties, and cities nationwide to enhance their IHD adoption and capacity.

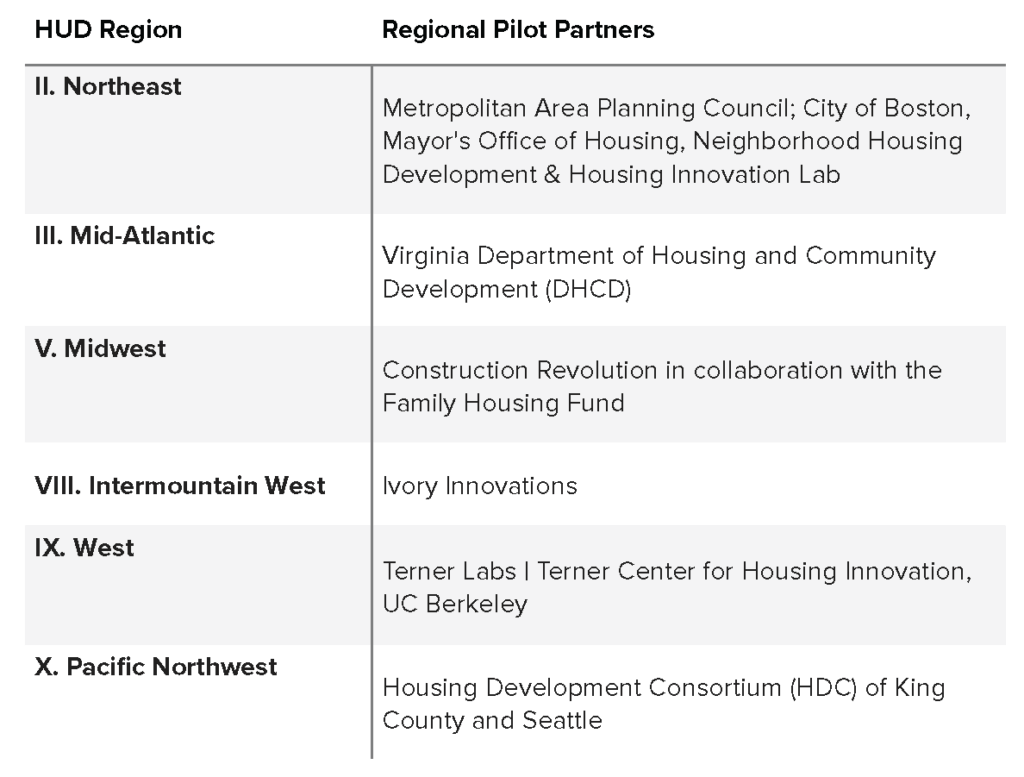

Over several years, MOD X has collaborated with key partners in multiple regions across the U.S., including the Northeast, Mid-Atlantic, Midwest, Intermountain West, West, and Pacific Northwest (Fig.1). As part of this effort, each of these regions will participate in virtual workshops to develop tailored Regional Action Plans to increase housing supply through IHD.

Building on insights from these regional collaborations, MOD X is planning to organize two Regional Offsite Construction for Housing Summits. These in-person events will provide a platform for participating regions to present their Regional Action Plans thereby fostering knowledge-sharing among regions pursuing similar efforts. Summit participants will include state housing finance agencies, state code building offices, state economic development agencies, industrialized building program offices, industry representatives, and nonprofit representatives. The summits provide a key opportunity for federal and local leadership to contribute to a national framework to accelerate housing production, strengthen local economies, and expand affordable housing options. Expect more information about these events in the near future. In addition to Pilot Partners from the regions, the project includes Strategic Partners that provide fundamental knowledge, advocacy, and relational networking value. These partners include the International Code Council (ICC), ICC-NTA, Harvard Joint Centers for Housing Studies (JCHS), and Ivory Innovations. Ivory Innovations, a Utah-based nonprofit dedicated to catalyzing innovative solutions in housing affordability, has also partnered with MOD X to develop and launch a national Offsite Accelerator industrialized construction educational program designed to inform and assist regions to overcome knowledge barriers associated with offsite construction for housing. The Offsite Accelerator was developed to address the needs of a broad audience including finance and insurance professionals, AEC professionals. Developers, suppliers, building code officials, government officials, etc. The program includes the delivery of a 4-session interactive course supported by content illustrating offsite housing context, domestic and international case studies, technology, and delivery. Participants will benefit from a worldwide network of offsite industry, academic, government, and related nonprofit thought leaders. Sessions are a mix of core theory, practical application, and case study examples of projects and companies in the offsite housing industry from the U.S. and around the world.